Used Forklift Parts – Should You Choose Rebuilt Or Re-manufactured Forklift Parts ?

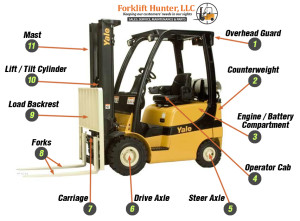

As you know forklift parts are very important part of any manufacturing firm. It used for many purposes like for lifting or manufacturing. But after sometime forklift parts have to changed or need to re- manufactured. When re-manufactured forklift parts, you have the options to take new parts which are more costly or you can get repaired them and save your money.

When dealing with old or used forklift parts, the best decision is to get used forklift parts that have been re-manufactured or repaired. This will confirm that you are getting those used parts that will really work well for a longer time period. Here are some tips are given for Re-manufactured Forklift parts:

1. Rebuilding Versus Re-manufacturing forklift parts:

Re-manufacturing of worn out or broken parts, is a best cost effective technique or way to the long run of machine. Re-manufacturing is better than just only rebuilding a damaged or broken part.

In the procedure of rebuilding a damaged part, the only those parts which are broken or damaged are replaced. This means that you have not to buy other wearable parts.

In the procedure of rebuilding a damaged part, the only those parts which are broken or damaged are replaced. This means that you have not to buy other wearable parts.

Re-manufactured Forklift parts give the best assurance in used parts since the part is taken separately and cleaned then all forklift parts are replaced.

The forklift components are replaced irrespective of time when purchased. This confirms that any part within the forklift is new therefore offering a longer life then the used part. The cleaning process will different depending on the used forklift parts in the re-manufacturing.

2. Replacing And Testing Parts

The forklift engines are oven cleaned after complete work. The machine can be re-manufactured with some parts being replaced, which contain the rings, pistons, spark plugs, bearer, valves and lifters along with the valve spirals. After reassembly, the machines are verified or tested to confirm that there are no problems or leaks with noises, oil pressure or any vacuum.

Transmissions are also be cleaned after being disassembled, and then they are densely washed. A systematic review is done to confirm there are no cracks in the gears. Bushings, Bearings and seals are replaced. Replacement parts meet O.E.M conditions that are used on part in the transmission.

3. Wearable Parts

The starter, alternator, torque converters, water pump, and steer axles all can also be re-manufactured forklift parts that have to be replaced or repaired. The control card is the automated control in an electric forklift; this can also be re-manufactured by changing all worn and old parts. Unlike all other parts, the controller card should also have worn and old parts replaced.

4. OEM Specs:

Upon reassembly, the re-manufactured forklift parts will be systematically checked to confirm that they are of top quality before being sold. Make sure that when you search to find re-manufactured parts then you have to undergone systematic examination and testing. OEM specification replacement parts should be used on steer axles, transmissions and engines.

With the help of trader, you can confirm that the used forklift parts that have to re-manufacture meet all conditions. You can see that there are many types of details that used in re-manufacturing. Lots of dealers are also available on internet who gives you best suggestion regarding re-manufacturing.